INSPECTION AND TEST EQUIPMENT

Test benches and equipment built to last

EFS has developed real expertise in the design and manufacture of test equipment. They are designed to check equipment in a laboratory or production environment.

This equipment is used in sectors as varied as the automotive industry, transport and research institutes.

Our test benches are always designed to be upgradeable, easy to maintain and highly reliable

Some of the test equipment presented here has been in production for over 15 years and is still being maintained. They operate 2×8, 6 days a week, 280 days a week.

OUR BUSINESS: designing test equipment for equipment inspection

From design to manufacture throughout the life of the product

Worldwide presence

Innovation

Service rate > à 90 %

TEST EQUIPMENT DESIGNED TO LAST

Perfectly adapted test benches

Our equipment is always perfectly adapted to the specifications we are asked to meet, in terms of both the test to be carried out and the environment. The ergonomics of using the machine is also a major point, as important as the test itself.

Our aim is to define simple, pragmatic equipment that can be used by everyone. Similarly, the scalability of the equipment will always be considered at the design stage, so as to be able to respond to long periods of use and guarantee maintainability over several decades.

A space is reserved for future extensions to the bench. Everything is referenced to facilitate maintenance and enable the bench to be upgraded at the right time for our customers. Every result presented is a physical measurement that everyone can understand. If the results are based on complex calculations, the basic measurements used for these calculations are also presented in order to guarantee the results obtained

Whatever test problem you have in mind, don’t hesitate to submit it to us so that together we can design test equipment that is reproducible, safe and reliable over the long term.

Benches made to be checked and calibrated

All the measurements taken on our test benches can be verified and calibrated. Depending on the complexity of the measurement, it can be checked at one point, two points or more, depending on the accuracy and linearity required.

Most simple measurements (temperature, pressure, continuous flow, etc.) are verified at two points and corrected by a gain and an offset.

Discontinuous, high-frequency measurements are calibrated using several averages to optimise accuracy. Gain and offset compensations are applied to different speeds to ensure accurate measurements.

Each measurement point is studied with the customer and defined in terms of its expected long-term accuracy, and therefore defined in terms of the calibration and accuracy to be maintained.

Upon request of our customers and to maintain their production certifications, we offer an on-site verification service for our equipment to guarantee the measurement accuracy provided by our test benches.

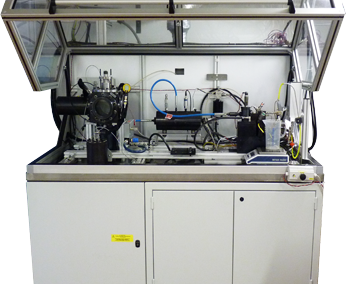

Examples of our test and inspection benches

Download our TEST AND CONTROL BENCH brochure

Envoyer le lien à :

They trust us