ONBOARD HIGH-VOLTAGE BATTERY CHARGER FOR 100% ELECTRIC MINI-EXCAVATOR

IN-VEHICLE HIGH-VOLTAGE BATTERY CHARGER

Our engineering department has developed a project for an onboard high-voltage battery charger

The Elexc project is the result of a partnership with a major automotive group, as well as a team of six partners. This collaboration has led to the development of a fully electric mini-excavator prototype.

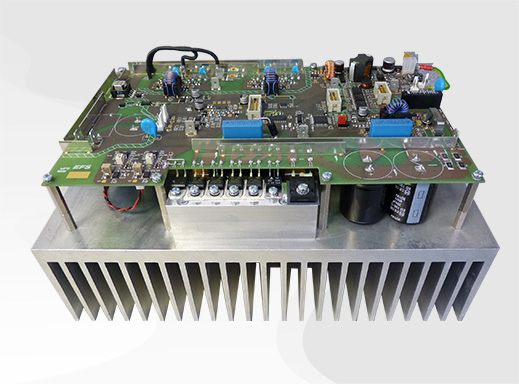

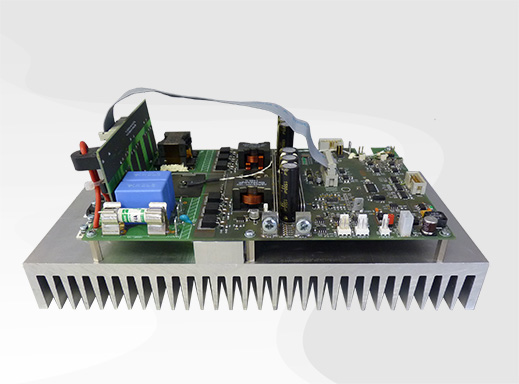

EFS was responsible for the management of electrical energy conversion and designed these two pieces of equipment:

- A 3 kW charger for high-voltage battery (420 V – 700 V).

- A 1.5 kW low-voltage converter (16 V – 30 V).

IN THE BEGINNING

PARTNERSHIP

ADVANTAGES

Noise level reduced by a factor of 8 compared to the traditional mini-excavator,

Operating costs reduced thanks to an overall energy efficiency 10 times higher.

ONBOARD HIGH-VOLTAGE BATTERY CHARGING SYSTEM

Customer problem

At a time when environmental issues are at the heart of concerns, a major automotive group aims to develop a 100% electric excavator.

EFS response

This innovative project immediately appealed to our company, which is already deeply involved in the design of equipment in the field of energy conversion. Its goal is the design and development of a 100 % électric mini-excavator, optimized for minimal energy consumption.

The main focus areas identified for this onboard high-voltage battery charger project are:

- electrification of the actuators

- Generation, storage, and management of energy. The final step was the integration into the vehicle

EFS was in charge of the electrical energy conversion system management.

Advantages of the on-board high-voltage battery charger

The results obtained fully met the customer’s expectations.

- The all-electric mini-excavator achieves the same performance levels as a traditional mini-excavator fitted with a diesel engine: the same force, speed and useful power.

- In addition to the ‘autonomy of use’ aspect, the cost of electric power and the reduction in the number of maintenance operations mean that the equipment’s operating costs can be significantly reduced

SEE OUR BROCHURE

Envoyer le lien à :