GAS, GASOLINE, DIESEL INJECTOR QUALIFICATION SERVICES, NEW OR USED

We use state-of-the-art equipment to offer you comprehensive services for the qualification of your injectors.

This system includes an INJETVISION vision chamber combined with several IFR flowmeters for a complete and precise analysis:

- IFR 600 for car and truck injectors

- IFR 6000 for train and small boat injectors

- IFR 40000 for cruise ship and power plant injectors

- IFR Gaz for hydrogen and CNG injectors…

We offer measurement and characterization services for all common rail injectors available on the market, whatever the fuel type: diesel, gasoline, ethanol, methanol, ammonia, hydrogen (H₂), CNG and more.

Our service applies to both new and used injectors, with precise validation over their entire operating range.

EFS has over 35 years’ experience in testing injection systems for internal combustion engines. We have all the equipment and know-how in-house to qualify your injection systems.

A SERVICE 100% DEDICATED TO THE QUALIFICATION OF YOUR INJECTORS

Tests examples for injector qualification services

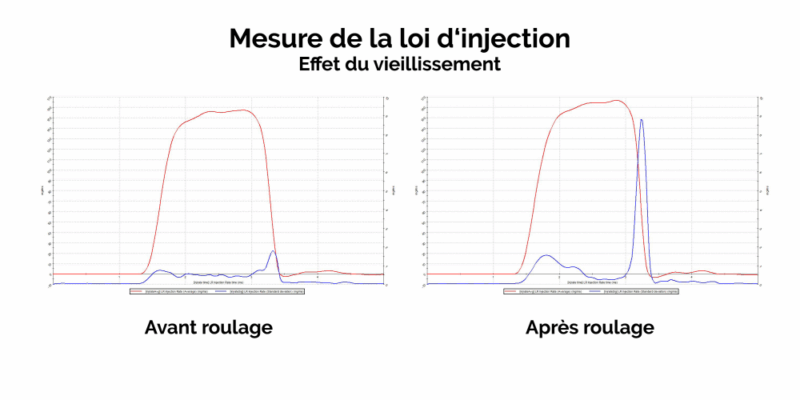

- Determine injector clogging (measurement before and after running)

- Compare injectors (old and new generation)

- Characterize injector (reference or prototype injector)

- Perform measurements with specific fluid (to analyze effect on injection generation)

- Analyze injector failures (analysis of instabilities in flow or spray generation, spray deformation, etc.).

Injector’s flow qualification

IFR: Mass shot-to-shot injection measurement device

- Measurement ofinstantaneous injected fluid (mass or compensated volume) in instantaneous, averaged and cumulative values

- Measures up to 10 differentiated injections per revolution

- Real-time display of the injection rate curve (standard deviation on the injection rate to study injection stability)

- Injector control study: measurement of injector opening and closing times (injector opening and closing faults, etc.).

- Injector mapping (MAP)

- Measurement of injector leaks (temperature and flow rate in g/min of injector leak).

Injector spray qualification

INJETVISION: vision chamber to study jets from high-pressure injectors in an inert atmosphere (Nitrogen or CO2) up to 50 bars (±0.5 bar).

Parameters measured:

- Jet penetration (mm)

- Percentage of jet penetration (%)

- Jet opening angle (degrees)

- Jet surface area (mm²)

- Jet volume (mm³)

- Symmetry

- Spray cone angle in lambda view (degrees)

- Angle λ of a spray in lambda view (degrees)

- Angle α of a spray (degrees)

- Inter-spray angle (degrees)

- Circularity.

You need to characterize your injector but don’t have the necessary equipment? Are you carrying out fouling measurements on a vehicle and would like to analyze the impact on the injector, before and after? ? CONTACT US.

We qualify your injectors according to rigorous protocols, using state-of-the-art equipment and recognized expertise. Our dedicated service guarantees a reliable diagnosis and full traceability. Each time we work on your injectors, we issue a detailed, independent and strictly confidential report.

Download our brochure

COMMON RAIL INJECTOR QUALIFICATION

Send download link to:

Our distributors

They trust us