Solutions d’équipements industriels

Secteurs d’activités

Automobile

Automobile et poids lourds

Équipements & Travaux public

Engins de chantier, installateurs d’infrastructures

Produits électriques et électroniques

Éclairage, électricité générale, micro-électronique

Eau

Eau potable,

eaux usées, eau de process

Transport

Aéronautique, Ferroviaire, Maritime, Véhicules lourds

Industrie lourde

Métallurgie

Instituts de recherche

Laboratoires universitaires, EPIC, EPCE

Énergie et Chimie

Production et distribution d’énergie, pharmaceutique

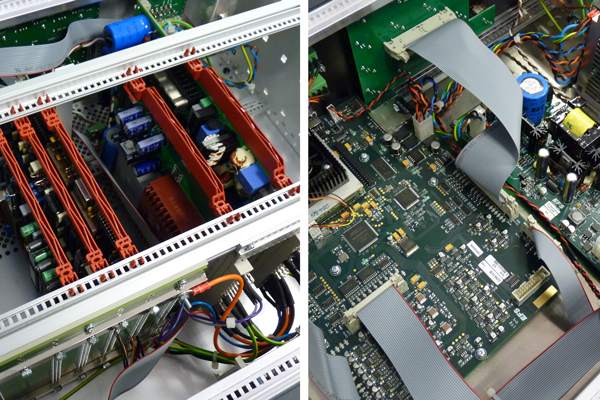

L’ expertise d’EFS

Conception de produits innovants

Électronique – Mécanique – Logiciel -Automatisme …

Production petites et moyennes série

Approvisionnement des composants Assemblage et tests

Gestion de projet co-développement

Idée – Solution – Industrialisation – Production – SAV … la contribution d’EFS s’adapte à chaque situation

Ils nous font confiance